|

|

|||||||

| Home | Forum | Online Store | Information | LJ Webcam | Gallery | Register | FAQ | Members List | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Display Modes |

|

|

#21 | |

|

Senior Member

Join Date: Apr 2010

Posts: 6,856

|

Quote:

x2....literally because I would need two

__________________

www.facebook.com/Teamsewer |

|

|

|

|

|

|

#22 |

|

#1 on fishstick's hitlist

Join Date: May 2011

Location: Sea level

Posts: 1,478

|

Have you thought about replacing the lines with 200lb coated cable? A friend did this to an outback and it's worked fine. Not sure why he replaced it in the first place though.

__________________

MLPA- My Largest Poaching Area

|

|

|

|

|

|

#23 |

|

Senior Member

Join Date: Aug 2011

Location: West Covina, CA

Posts: 434

|

Very ingenious rig to prolong the life of the rudder line, Tony!

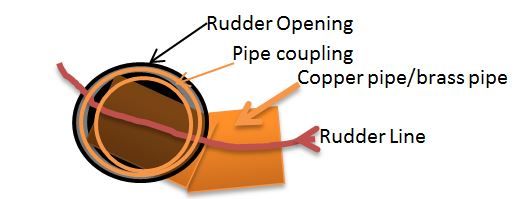

As far as having a coating on the wire such as Teflon, plastic, enamel.. and so on, it only helps for awhile but since the rubbing occur at the plastic edge, it will eventually start to protrude through the surface and slowly eat away at the braided line. My only suggestion is to cut a piece of brass, copper, or any soft metal that is less corrosive to saltwater and bend it to conform the shape so it can take the friction away from the plastic edge. 1/4 copper water metal piping with the fitting might be the best option and spray Teflon inside since the inside is smooth and polish.

Last edited by Rambo; 09-18-2014 at 09:51 PM. |

|

|

|

|

|

#24 | |

|

Daddeo

Join Date: Jul 2010

Location: OC

Posts: 660

|

Quote:

To understand your issue better, I acquired a PA14 and had my resident Junior engineer-in-training evaluate your problem with the steering cable failure... IMG-20140920-01852.jpg Here is Rockin’ Rolan with his eye on the problem… After thorough inspection of the steering cable system and geometry, we found the following suspect failure areas... IMG-20140920-01861.jpg The probable cause of failure is the contact friction-abrasion on the spectra caused by the angle of the cable as it relates to the fer rule/hard grommet. Furthermore, when tension is increased, the side-effect (pun intended) is increased abrasion exacerbated by higher tension-ing of the spectra cable (think of a bow-saw). PA_FRICTION.jpg Your suggestion of an ultra-smooth ferrule would last longer, but still may cause friction in the long run. Further we have determined the root cause of the failure is the linear direction of the cable going from the pulley to the rudder post bell crank. The existing angle causes friction at the ferrule/grommet. This geometry acts like a cable saw on the feed-through ferrule. Problem is the ferrule material is harder than the spectra cable causing contact abrasion and wears down the spectra first . If you can change that angle with an extra pulley etc., we at Redsledteam think it will resolve the problem.   |

|

|

|

|

|

|

#25 |

|

LOWSPARK

Join Date: Dec 2013

Location: CARLSBAD

Posts: 251

|

Linear direction !

If I can't go fishing the next best thing EVER is the intertainment value of BWE. A reality show is so close !! I can see Tony with his first emmy or oscar!!!

|

|

|

|

|

|

#26 | |

|

Large Member

Join Date: Jul 2012

Location: La Verne, CA

Posts: 1,011

|

Quote:

http://www.pricepoint.com/Brand/Alli...-Cable-Kit.axd http://www.pricepoint.com/Brand/Alli...-Cable-Kit.axd |

|

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|